For those who have seen my website http://www.celticempire.com/ , you may have seen under Celtic Leather, a card case that was purchased 27 years ago by "Robb" and was lost several times in some very remote places but always returned. Well this Christmas Robb decided that replicas or similar card cases would make nice gift for a number of associates and friends.

I should like to share with you the steps in making these "CC's". The leather pieces are cut in large numbers from 6oz calfskin. Once cut the edges are airbrushed in tightly packed bundles, then burnished before the thin line is added just for a finishing touch.

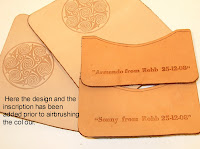

The next step is to emboss or rather impress a design onto the leather. In this case the "Newgrange" spirals, adapted from the burial mound on the banks of the river Boyne in Ireland, was the inspiration for this design. Today access is rather limited to this megalithic tomb, but in August 1984 people were allowed into the tomb with little or no restrictions. On the left is a picture of the design pressed into the leather beside the actual engraved block used in this instance.

Next we have the inscription or lettering that 'Robb' wanted on the inside of the card cases for his friends. The lettering used is moveable type set in a "Halvorfold-Kwikprint" machine and is changed for each separate name. Needless to say the type has to be choosen to fit within the limited area of the inside pocket.

Next the front part of the card case are airbrushed in the desired colour.

Here you see burgundy or 'Cordovan' a name derived from the city in Spain called Cordoba, which was given to it by the Moors when they occupied Spain and brought their skills in leather craft with them.

Now the assembly of the parts are glued together and then sewn with matching colours of thread. Burgundy on top and natural on the bottom. In large 'Machination" versus 'Manufacturers' ( manu = hand, facture= make), these are fed into a machine and sewn a precise distance from the edge. No hands needed to guide the the pieces through the machine.

Once sewn the edges are buffed and the corners are put on individually. In many commercially produced leather items there are only corners on the front for appearance sake. I prefer to put corners on all sides so as to ensure that the item will last for a lifetime. For me it is very rewarding that someone like Robb came back after all these years to show me that although well worn, the function of the card case he bought so long ago was mantained.

Once sewn the edges are buffed and the corners are put on individually. In many commercially produced leather items there are only corners on the front for appearance sake. I prefer to put corners on all sides so as to ensure that the item will last for a lifetime. For me it is very rewarding that someone like Robb came back after all these years to show me that although well worn, the function of the card case he bought so long ago was mantained.

Through the magic of the digital camera, I am able to post an image ( on the left) of one of the finished card cases that Robb is going to give to his friends and associates. I sincerely hope that many years hence they will also look back upon Christmas 2008 with fond memories and enjoy the function of this simple but most useful of leather articles.

No comments:

Post a Comment